Our Quality Policy

As Europe’s leading manufacturer, Teknorot operates in 18 different product groups, including ball joints, control arms with ball joints, tie rods, steering link assemblies, tie rod ends, control arms without ball joints, control arm bushings, rubber components, stabilizer links and stabilizer link bushings, repair kits, Z-links, Z-link kits, pressed steel control arms, and aluminum and steel forged ball-joint arms.

Adopting an advanced technology approach, Teknorot is Europe’s largest aftermarket manufacturer of suspension and steering components for passenger cars and light commercial vehicles. Founded in 1992 with 100% domestic capital, Teknorot began its journey in the industry and today continues its manufacturing operations in the Düzce Organized Industrial Zone with an extensive machinery park. Together with its global facilities, the company provides services through a wide production area and a comprehensive organizational structure. In line with the growth and increasing demand of the aftermarket, our Düzce facility—equipped with state-of-the-art technology—began operating at full capacity in 2008.

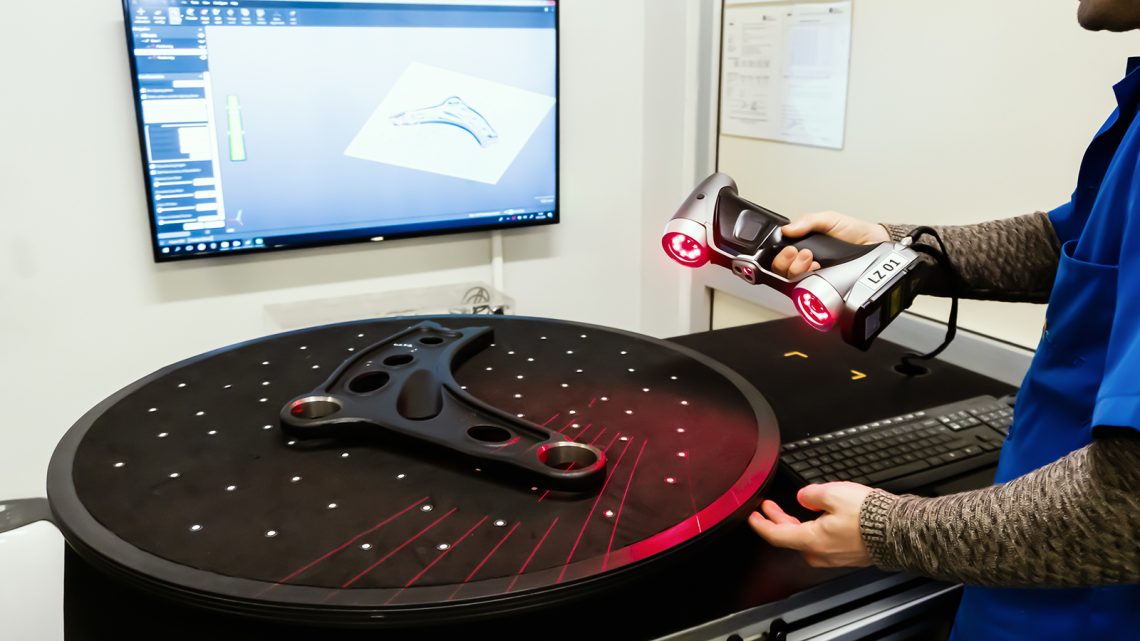

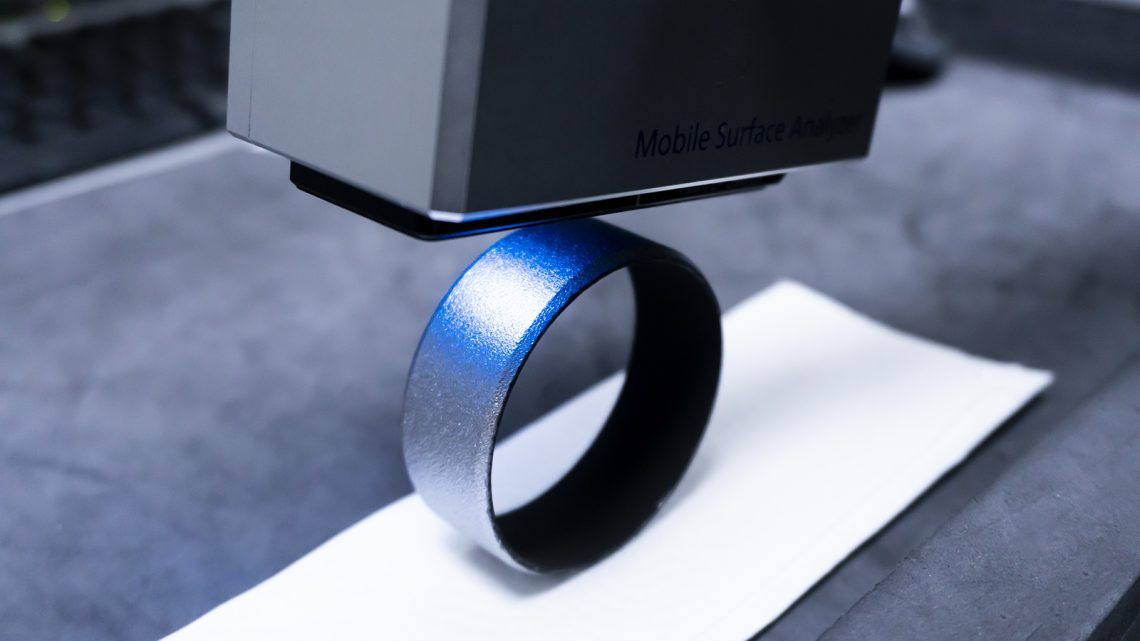

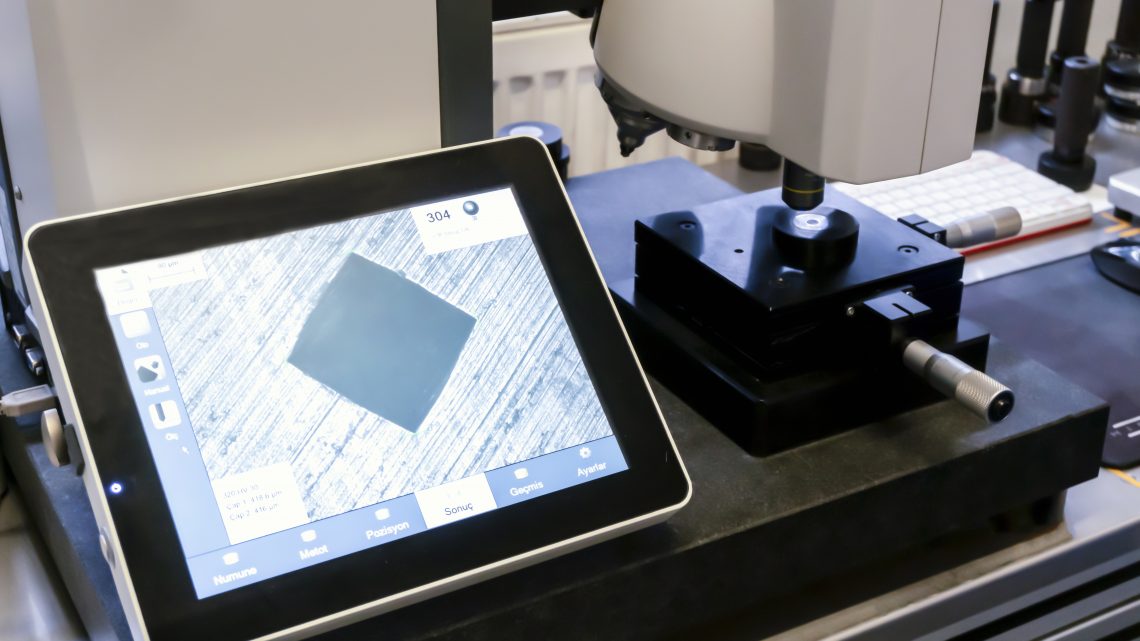

Never compromising on quality and placing customer satisfaction at the forefront, Teknorot achieves maximum equipment standards and quality across all product groups through its advanced technology philosophy.

With the goal of continuing to manufacture the most reliable, durable, and highest-quality product groups in its field, Teknorot maintains its leading position in the market.

The Düzce production facilities represent not only advanced technology but also new production methods and a high-quality manufacturing approach for Teknorot.

A global brand in quality: Teknorot

As one of the most reliable companies in its field, Teknorot maintains its leadership and exemplary position through its core principles. The company continuously expands its product range and offers its valued customers internationally standardized products—manufactured in-house and proven through quality, durability, and lifetime tests—including tie rod ends, tie rods, aluminum and steel forged ball-joint arms, pressed steel control arms, Z-links, and bushing product groups.

Our Quality Policy

- To provide our customers with high-quality products that meet their expectations,

- To carry out all activities from order receipt to delivery with customer satisfaction as the primary focus,

- To ensure management support and continuous involvement,

- To align all employees with company objectives through a quality-driven philosophy, fostering teamwork while developing their knowledge, skills, and competencies, and encouraging innovative and creative approaches,

- To create an efficient, productive, and lean working environment through continuous improvement in order to minimize natural resource consumption and losses across all activities,

- To establish mutually beneficial, development-oriented relationships with our suppliers, recognizing that supplier development directly contributes to company growth,

- To comply with all applicable legal and other requirements in order to provide a healthy, safe, and human- and environment-respectful working environment, prioritizing the elimination and reduction of risks in our activities and services,

- To support activities and practices that contribute to the improvement of societal welfare within the scope of our resources, in line with our social responsibility principles.

We commit to continuous improvement of our quality management systems in line with the principles stated above, and to complying with all applicable laws, regulations, and other requirements across all our processes.

Our Energy Policy

TEKNOROT OTOMOTİV A.Ş. operates in the automotive spare parts sector. TEKNOROT management is committed to maintaining and strengthening the company’s competitiveness, profitability, legal compliance, and energy efficiency, and to ensuring the effective implementation of sustainability principles.

In line with our Energy Policy, we commit to:

- Providing a framework for the establishment and review of energy objectives and targets; ensuring access to information, resources, and support necessary to achieve these objectives; and regularly reviewing and updating them,

- Continuously improving and documenting our Energy Management System and energy performance in accordance with the purpose and scale of our organization; communicating it to all employees; reviewing it; and ensuring it remains up to date,

- Monitoring and complying with all applicable laws, regulations, and other requirements related to energy,

- Using appropriate resources and technologies to keep energy consumption under control,

- Reducing energy consumption; implementing continuous improvement initiatives related to energy efficiency; applying these initiatives and monitoring their results,

- Using energy-efficient products, procuring services that support energy efficiency, and prioritizing energy efficiency in design activities in order to improve energy performance,

- Contributing to raising awareness of energy efficiency not only through training our employees, but also by informing our suppliers, subcontractors, and visitors.

General Manager

Cevat ASLAN