Bushing Production

Teknorot has been producing and dealing bushes to all over the World. The bushes are either packed and shipped directly to our customers or used as a component of Wishbones, Link Stabilizers, Track Control Arms and Lateral Arm.

Teknorot has been producing Engine Mounting, Transmission Mounting, Strut Mounting, Rubber Buffer for Suspension, Exhaust Mount and Antiroll Bar Bushes beside bushes.

Teknorot is the leading manufacturer which produce its bushes inhouse and has one of the biggest bushing production plant in its sector.

Bushing; smart connection between rubber and metal

Due to the their distinctive effect on driving characteristic and safety, and the increasing number of track control arms and sheet metal wishbones used in current chassis configurations, lead to the increase of the use of rubber / metal parts.

The vulcanized connection between natural rubber and metal is specially designed considering the vibrations on the vehicle and these designs make a significant contribution to driving comfort.

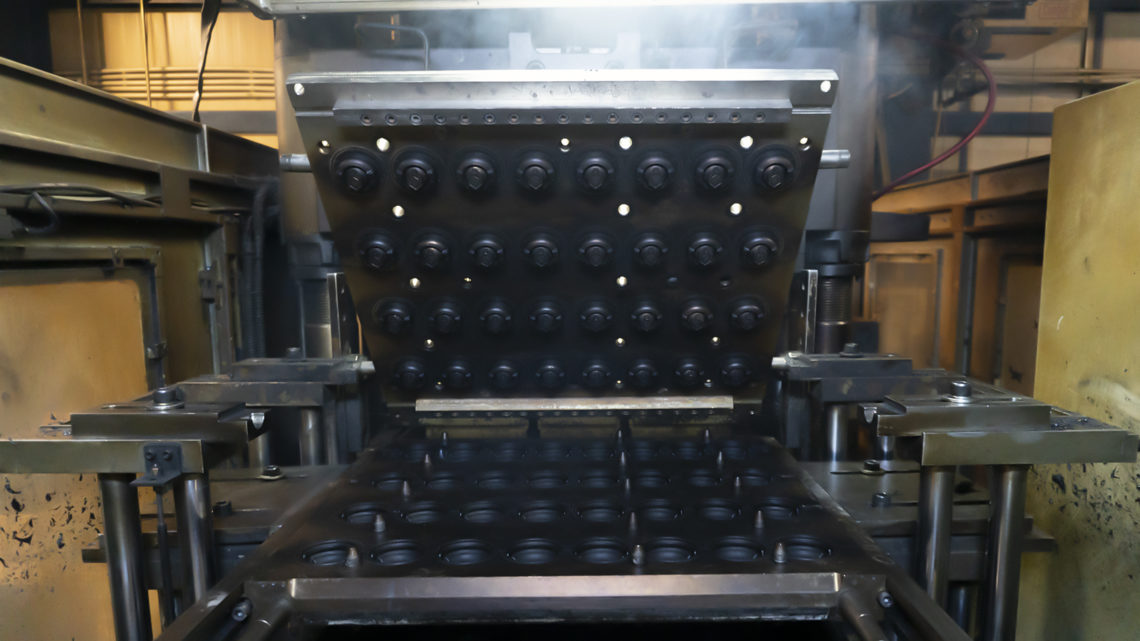

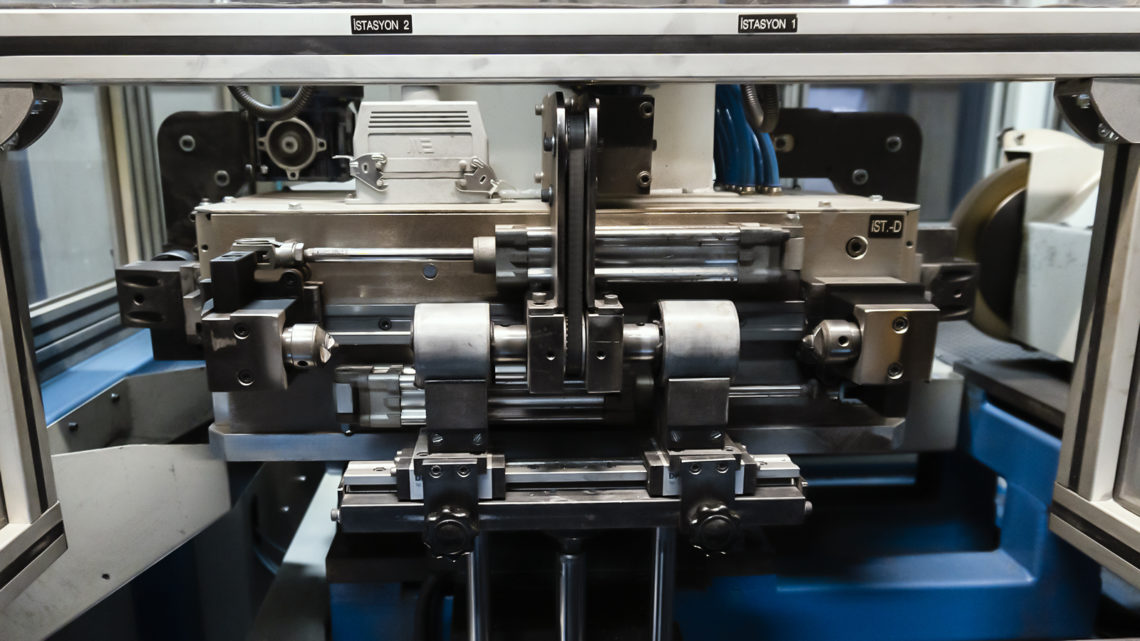

The bushing production department works as follows;

- The surface treatment of metal components to be used in the vulcanization process

- Vulcanization of metal components and natural rubber mixture, by using transfer and injection molding presses in which all processes are monitored and controlled by computer

Each bushing of Teknorot offers high durability and driving safety;

- Excellent compatible material properties

- Damped chassis vibrations

- Excellent assembly

Bushings are safety and comfort components, and designed uniquely to reduce vibration and noise when the vehicle is in motion. Bushings help vehicle’s suspension parts to connect to chassis. Bushing parts can be natural rubber depending on design of vehicle; however, can be produced half natural rubber half metal. In the recent years, high-enduring engineering plastics have begun to be used instead of metal.

In the bushing production, all of the raw materials imported from the outside primarily pass through a rigorous input quality control process. If metal components is used for production, the process begins with forming metal pipes by eccentric presses. Metal pipes shaped in appropriate quality conditions. Rubber is subjected to washing, sanding, degreasing and painting processes so that the metal and metal surfaces can be adhered to each other perfectly before entering the vulcanization presses. Surface-cleaned metal parts are painting at fully automatic painting line to keep the desired paint coating thickness under constant control.

After required surface operation for adhesion, metal components are processed with rubber paste, which possess cold feeder system. Then, final product can be obtained. The specifications of the rubber paste used in the vulcanization operation are exactly the same as the original part and supplied from A-class suppliers. They are kept in the cold air storage until production to protect the technical properties of the rubber paste.

The vulcanization operation and the necessary deburring process is followed by a chrome or phosphate plating that is applied on the body. This prevents products’ corrosion on different usage conditions of the vehicle. Every step of the production and quality control operations is carried out by qualified personnel. Ensuring high driving safety and continuity of strength is the common mission of the team in all bushing production operations. The bushes are either packed and shipped directly to our customers or used as a component of Wishbones, Link Stabilizers and Track Control Arms.

About Kautek

Kautek is the producer of rubber and metal products in the passenger cars and light commercial vehicles segments of the automotive sector. Kautek is one of the associations of Teknorot.

With over 30 years of experience in our sector, Kautek brand was created in 2012 to meet the requests of the valuable customers and to provide a better service in the field of rubber metal.

The vision is to follow closely the demands in the sector and to produce goods and services with highest quality that goes beyond our customers expectations; and to become a growing, strong, leading and respectable world brand.

The mission is to carry Kautek to the future by constantly increasing the quality and services of the company, which embraces the principles of persistence, honesty, innovation, determination and leadership.

Kautek’s product groups are Bushes, Engine Mount, Transmission Mounting, Strut Mounting, Rubber Buffer for Suspension, Turbo Hoses, Shaft Propeller, Exhaust mount and Antiroll Bar Bushes. Kautek is the manufacturer and distributor of these product groups.

Kautek is the one of the most leading rubber to metal parts producer and distributor in Turkey and Europe.

Please visit http://www.kautek.com.tr/ for detailed information about Kautek.